In industries where a fraction of a millimeter can mean the difference between success and failure, precision is everything. From the sleek curves of an aerospace fuselage to the intricate components of a medical device, the ability to cut metal with exacting accuracy is the backbone of modern manufacturing.

If you work in an industry that utilizes metal parts, understanding the nuances of different cutting technologies is essential. To help you better understand it, we’re here to explore the best methods for high-precision metal cutting.

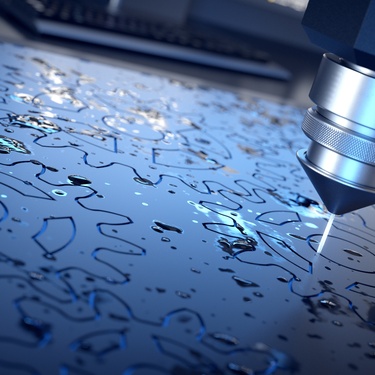

Laser Cutting

In laser cutting, a focused beam of high-intensity light is used to cut materials by melting, burning, or vaporizing right through them. It is a favorite in many shops for good reason. The process offers incredible precision, capable of creating complex geometries with clean edges that often require no further finishing. Because of that, along with many other reasons, laser cutting plays a big role in thin-gauge metal fabrication.

Also, since the laser beam is so narrow, material waste is kept to an absolute minimum, making it cost-effective for expensive alloys. You will find laser cutting heavily utilized in electronics and automotive manufacturing, where speed and detail are paramount.

Plasma Cutting

Plasma cutting is another popular method for precision metal cutting that works by sending an electrical arc through a gas that passes through a constricted opening. The gas heats up to a point where it enters a fourth state of matter—plasma—and melts the metal.

While it might not match the extreme intricate detail of a laser, it’s still quite accurate. Plasma cutting is popular due to its speed and cost, especially when used with conductive metals like steel and aluminum. It is a workhorse in industrial construction and salvage operations where rapid throughput is more critical than microscopic precision.

Waterjet Cutting

Imagine a stream of water so powerful it can slice through steel. That is the essence of waterjet cutting. By mixing water with an abrasive substance like garnet and pressurizing it to extreme levels, this method erodes material away along a precise path.

The biggest advantage here is temperature control. Unlike lasers or plasma, waterjets are a “cold” cutting process. This means there are no heat-affected zones (HAZ), preventing warping or changes in the metal’s structural properties. It is the go-to choice for thick materials or metals sensitive to high temperatures.

Electrical Discharge Machining

For the hardest metals that would chew up traditional tools, electrical discharge machining (EDM) is the answer. This non-contact process uses electrical sparks to shape metal. The cutting tool (electrode) never actually touches the workpiece; instead, a series of rapidly recurring current discharges between two electrodes removes material.

EDM is unrivaled when creating intricate shapes in hardened steel or titanium. It is indispensable in tool and die making, as well as in the aerospace and medical sectors, where components must meet rigorous specifications.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.