If you operate heavy equipment, you know the parts take a beating. But have you ever thought about what makes those parts tough enough to handle extreme conditions? Understanding the common materials used in heavy equipment parts is key to knowing how your machines work, how they endure, and how to maintain them effectively. This guide dives into the most widely used materials and why they matter to your equipment’s performance and longevity.

Steel

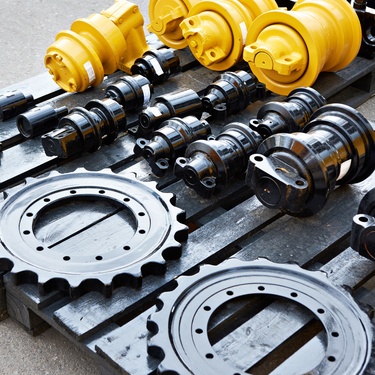

Steel is a workhorse material in heavy equipment and for good reason. With its unmatched strength and durability, steel can withstand the immense demands placed on construction and mining equipment. That’s why material strength is one of the most important factors to consider when choosing undercarriage parts.

Carbon steel, for instance, is famous for its toughness and resistance to wear, making it a go-to choice for parts like frames and gears. Alloy steel, which mixes in elements like chromium or nickel, doubles down on durability and can resist more extreme environmental conditions. Meanwhile, stainless steel brings corrosion resistance to areas like blades or hydraulic fittings, making it invaluable when equipment is used in wet or corrosive environments.

Aluminum

Aluminum is another superstar when it comes to heavy equipment, primarily because of its lightweight and corrosion-resistant properties. Its ability to handle high temperatures while remaining lightweight makes it an ideal candidate for engine parts like pistons and housings. Plus, its resistance to corrosion ensures that these components maintain their integrity, no matter how grueling the work environment is.

Rubber

Both natural and synthetic rubber play vital roles in heavy equipment thanks to their flexibility, shock absorption, and sealing properties. The tires on your loader? They’re made to grip different terrains with natural rubber. Hydraulic hoses? That’s synthetic rubber doing the job. Seals around moving parts? Rubber creates barriers that prevent leaks and keep things running smoothly.

Plastics

Plastics might sound out of place alongside steel and aluminum, but they’re incredibly versatile. Polyethylene and nylon are crucial because they offer impressive resistance to chemicals and wear. These qualities make them reliable in parts like protective liners or bearings. Plastics also handle intense friction, extending the lifespan of parts and reducing the need for frequent replacements.

Understanding Heavy Equipment Components

Recognizing the common materials used in heavy equipment parts gives you a clearer picture of how your machines operate and how to keep them functioning at their best. Knowing your steel from your aluminum or when to use rubber over plastics can make a meaningful difference in how you care for your equipment, ensuring it runs longer and works harder.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.