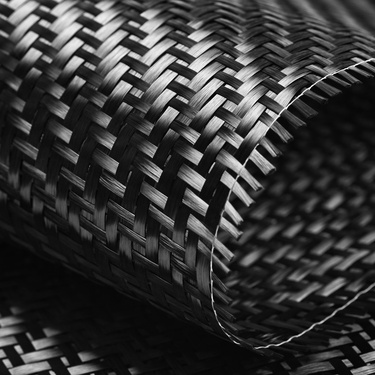

Carbon fiber is a buzzword in engineering and manufacturing, and for good reason. Its unique properties make it an indispensable material for aerospace, automotive, sports equipment, and other industries.

This lightweight yet incredibly strong material isn’t just a passing trend; it’s revolutionizing modern design and production processes. Here are a few reasons why carbon fiber is popular in many industries and how it opens up exciting opportunities for innovation.

1. High Strength-to-Weight Ratio

One of the most celebrated features of carbon fiber is its incredible strength relative to its weight. It’s up to ten times stronger than steel and almost five times lighter. This makes it ideal for industries like aerospace and automotive, where reducing weight without compromising strength significantly improves efficiency.

Passenger aircraft with carbon fiber components consume less fuel, reducing operational costs and environmental impact. If your project requires a material that maximizes strength while minimizing mass, carbon fiber deserves a top spot on your checklist.

2. Exceptional Durability and Longevity

Unlike materials that degrade under stress or environmental exposure, carbon fiber retains its integrity over time. In the sporting goods industry, carbon fiber tennis rackets and bicycles stay in premium condition even after years of heavy use. If you’re looking to create durable components that won’t need constant replacements, carbon fiber is an investment that pays off.

3. Design Flexibility and Customization Options

Engineers and designers love carbon fiber because it’s incredibly versatile. The material is molded into intricate shapes and while maintaining strength and lightweight properties. This flexibility is vital for the automotive and consumer electronics industries, where precise designs and unique aesthetics often set products apart.

Using advanced materials is an emerging trend in metal fabrication, and carbon fiber composites are more durable and offer more design options. Its adaptability allows you to push creative boundaries without compromising functionality.

4. Corrosion Resistance

There’s no denying the negative impact of materials that corrode from exposure to moisture, chemicals, or extreme environments. Carbon fiber’s natural resistance to corrosion makes it a game-changer in sectors like marine, construction, and renewable energy.

Wind turbine blades from carbon fiber last longer and require less maintenance than steel. If your project demands resilience in harsh conditions, carbon fiber is a reliable choice that keeps performance intact while minimizing repair needs.

5. Thermal Conductivity and Stability

Carbon fiber offers excellent thermal stability and maintains its structural integrity in extreme temperatures. This trait is especially valuable in aerospace, industrial manufacturing, and electronics applications, where materials are subjected to intense heat.

Additionally, depending on requirements, carbon fiber composites may conduct or insulate heat. This versatility makes it an exceptional material for heat dissipators in electronics or thermal shields in high-temperature environments. If precision and thermal reliability are priorities, carbon fiber delivers unmatched performance.

From its lightweight strength to its adaptability and durability carbon fiber remains a popular material in many industries. Its ability to handle complex design challenges while offering long-term value makes it a go-to choice for engineers and manufacturers. Leverage this versatile material to unlock new levels of innovation and efficiency in your industry.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.