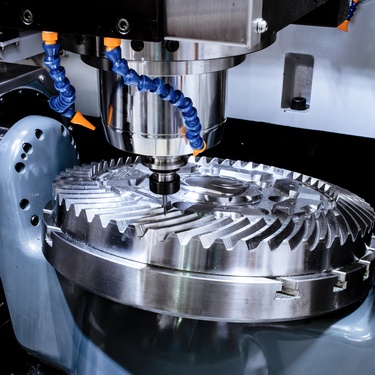

Computer numerical control (CNC) machines have revolutionized modern manufacturing by providing unparalleled precision, automation, and versatility in shaping various materials. These machines play a critical role in industries ranging from aerospace and automotive to furniture design and medical technology, enabling the production of complex parts.

Even the most advanced CNC machines require proper maintenance and performance optimization to unlock their full potential. By learning how to improve the performance of your CNC machine, you can achieve faster cycle times, reduce material waste, minimize costly downtime, and deliver consistent results.

Regular Maintenance Is Key

Preventative maintenance ensures your CNC machine operates smoothly for the long term. Regularly inspect essential components, such as the spindle, tool holders, and clamps, for wear and tear. Cleaning parts that come into contact with cutting materials can prevent debris buildup and ensure precise cutting. Check and replace lubricants based on the manufacturer's recommendations to avoid unnecessary friction or overheating.

Optimize CNC Programming

Efficient programming is a significant factor in CNC machine performance. Review and refine the tool paths in your G-codes using computer-aided design (CAD) and computer-aided manufacturing (CAM) software. Minimizing excessive tool movement and optimizing cutting paths saves time and reduces tool wear. Setting proper feed rates and speeds adapted to the machined material ensures smooth operations.

Upgrade Critical Machine Components

If your CNC machine is outdated, consider upgrading its components to improve performance. Common upgrades include increasing spindle speed, adding advanced cutting tools, and improving the control system. Evaluating the differences between stepper motors and servo motors will ensure you choose the best option for your needs. Investing in machine upgrades will help you stay relevant and ready in a competitive market.

Prioritize High-Quality Materials and Tools

Using high-quality materials and tools profoundly impacts your CNC machine's output. Cheap or low-quality tools can wear out quickly or break easily, leading to more downtime and costly repairs. Invest in reputable cutting tools from durable materials like carbide or high-speed steel for maximum longevity and precision. Quality inputs lead to better performance and a smoother machining experience.

Monitor and Adjust Environmental Conditions

The environment in which your CNC machine operates plays a critical role in its performance. Factors like temperature, humidity, and dust accumulation can impact accuracy and reliability. Extreme temperatures can cause thermal expansion in machine components, leading to inaccuracies. To mitigate this, maintain climate control in your workshop to ensure consistent working conditions. Installing air filtration systems also helps reduce dust-related issues, minimizing the chance of malfunction.

Improving the performance of your CNC machine is not a one-time effort but an ongoing process. You can significantly enhance your machine's efficiency and output through regular maintenance, smart upgrades, optimized programming, high-quality inputs, and controlled environmental factors. Adopting these practices ensures that your CNC machine remains a valuable and high-performing asset for many years.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.