Gearboxes in plastics manufacturing run under high loads, so when they fail, production stalls immediately. Drift out of spec stresses torque transfer systems and connected machinery, cutting dimensional accuracy, raising scrap, and compromising safety. Plant operators and maintenance leads can act quickly to prevent failures and keep production stable by recognizing mechanical vulnerabilities early.

Overheating During Continuous High-Speed Production

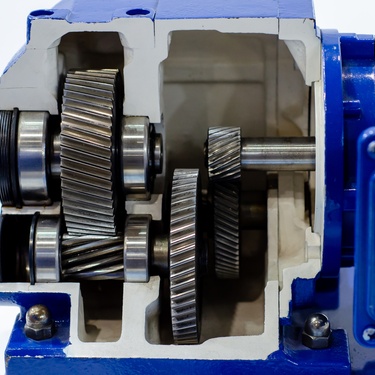

Heat builds quickly in gearboxes operating under long production cycles with minimal cooldown. Extrusion and thermoforming lines often generate internal temperatures that push oil past its protective viscosity range; as the lubricant thins, gear surfaces wear faster and friction spikes. Excessive heat swells seals and raises housing pressure, creating resistance at the shaft and slowing rotational efficiency.

Premature Bearing Wear From Torque Spikes

Torque loads change in real time during material jams, startup surges, or unsynchronized cycles. Bearing races absorb those shockwaves.

Over time, bearings pit, flake, or seize as clearances vanish under sudden stress. One common gearbox issue present in plastics manufacturing is premature bearing failure linked to torque instability and stop-start abuse.

Lubrication Contamination From Polymer Particulates

Fine plastic particles float inside every molding, extrusion, or compounding line, and infiltrate lubricant reservoirs through tired seals or vents. Even microscopic resin granules damage gears while circulating inside poorly sealed housings. Cloudy or discolored oil, metallic streaks, or sticky residue on the fill plug often signal contamination.

After intrusion starts, components lose protective film strength and wear accelerates. Closed-loop filtration adds protection, but regular oil analysis delivers the best early-warning signal. Regrind-heavy and blow molding cells see faster contamination; increase sampling frequency and inspect breathers and shaft seals during every planned stop to preserve service life.

Shaft Misalignment During Mold or Die Changeovers

Tool changeovers invite fast mistakes when drives get adjusted without realignment verification. Gearboxes mounted to uncalibrated molds or shifting die positions absorb load unevenly. Shafts misaligned during tool swaps create stress zones that accelerate wear across the rotational axis, so catching signs of misalignment early is critical for avoiding earlier gearbox failure.

After a few misaligned swaps, you may hear clicking or feel vibration spikes during gear transitions. Misalignment often escapes visual checks, and efficiency drops as rotational imbalance grows. Use laser-based alignment after each tooling swap to prevent shaft distortion and mounting damage.

Gear Tooth Fracture Due to Improper Backlash Settings

Gear teeth rely on precise clearance to absorb load without shock, and motor resets or new reducer installs can disrupt backlash without detection. Another common gearbox issue present in plastics manufacturing is gear tooth chipping caused by tight backlash following motor swaps or alignment shifts. Impact at the tooth root weakens the structure and triggers cascading failure across the profile.

Fractured debris circulates and chews nearby bearings and seals, pushing noise and temperature higher. Verify backlash during installation and recheck mesh quality after motor or coupling service. Always treat supplier template specs as benchmarks to meet exactly, not guidelines to approximate.

Torque transfer, thermal load, seal integrity, and alignment stability all depend on keeping systems within tolerance. Gearbox problems often start small, but a fast response separates a quick repair from a catastrophic rebuild.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.