Industrial hydraulic systems power some of the most demanding machinery on factory floors, in construction sites, and at manufacturing plants. When they fail, operations grind to a halt—and downtime costs money.

The good news? Most hydraulic failures are preventable with consistent, strategic maintenance. Whether you’re managing a collection of heavy equipment or overseeing a production line, these four maintenance practices will help you maximize uptime and extend the life of your industrial-grade hydraulic systems.

Maintain Proper Hydraulic Fluid Quality

Hydraulic fluid is the most critical part of a hydraulic system. Different applications require different viscosity grades and additive packages, so don’t assume that one fluid fits all. Using the wrong type can lead to reduced efficiency, component wear, and costly breakdowns. Always use the fluid that the system manufacturer specifies.

Regular fluid testing is equally as important. Check for contamination, viscosity changes, and temperature stability at scheduled intervals. Contaminated or degraded fluid accelerates wear on pumps, valves, and cylinders, often before you notice performance issues.

Keep the System Clean

One of the leading reasons that hydraulic systems fail is contaminated fluid. Even microscopic particles can damage a system over time. That’s why you need to replace filters according to your maintenance schedule, not just when they look dirty. Clogged filters also reduce flow and increase pressure, stressing the entire system. If you’re operating in a particularly dusty or harsh environment, consider shortening replacement intervals.

When replacing a filter, don’t overlook the hydraulic reservoir. Make sure it’s properly sealed to prevent dirt, moisture, and other contaminants from entering. A breather cap with a built-in filter can provide an extra layer of protection.

Monitor System Pressure and Temperature

Hydraulic systems operate within specific pressure and temperature ranges. Exceeding these limits—even temporarily—can cause premature wear or catastrophic failure. If you install pressure gauges at key points in the system and check them regularly, you should be able to avoid most temperature-related issues. If pressure readings drift outside the recommended range, investigate immediately. The problem could be anything from a clogged filter to a failing pump.

Temperature spikes are another red flag. Overheating breaks down hydraulic fluid and damages seals. Ensuring that the cooling systems are functioning correctly and that there’s adequate ventilation around hydraulic components are the best ways to address this maintenance issue for industrial hydraulic systems. Just keep in mind that you may need to add auxiliary cooling in hot climates or high-demand operations.

Replace Worn or Damaged Parts

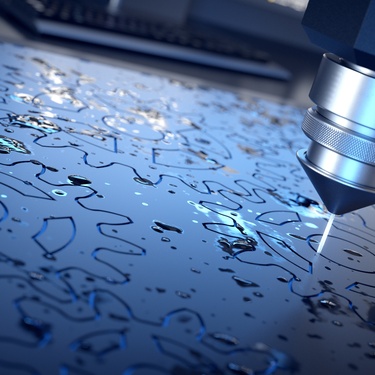

No component lasts forever. Hoses crack, seals wear out, and fittings corrode. Ignoring these issues invites leaks, pressure loss, and safety hazards. During routine inspections, look for signs of wear: frayed hoses, weeping seals, or loose connections. If a part is beyond repair, replace it promptly with a high-quality component.

Cutting corners with cheap replacements may save you money upfront, but it usually costs more in the long run via repeat failures and extended downtime. To ensure you get a replacement that will truly last, look into quality excavator hydraulic parts such as the Kawasaki hydraulic pump. No matter what you buy, be sure to keep a small inventory of critical spare parts on hand. Having a replacement hose or seal available can turn a potential day-long shutdown into a quick fix.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.