Selecting the appropriate material isn't just a task: it's the foundation for ensuring a project’s performance, durability, and success. In projects ranging from mechanical systems to creative industries, the stakes are high, and the material you choose can determine whether you’re on a path to reliability or unforeseen setbacks.

Choosing the right material can make or break projects, especially when you’re balancing quality, cost, and specific needs. Here's how to make effective choices, broken down by essential considerations.

Understanding Project Requirements

Start by outlining the specific requirements of your project. These include physical stresses, environmental exposure, and functional expectations. Materials perform differently under varying conditions, and aligning your selection to real-world scenarios helps reduce inefficiencies.

Ask yourself: What type of load or stress will the part handle, and what conditions will it face? Knowing these answers ensures you're focusing on the material’s purpose and strengths, rather than guesswork.

Balancing Quality With Cost

The budget doesn’t have to sacrifice quality if you're strategic. While high-budget projects allow for premium materials, even smaller budgets can find clever solutions.

Weigh material costs against their benefits to identify where you can save without compromising functionality. For example, industrial designers often compare polymers like acetal and PVC for cost-efficiency while maintaining durability.

Quick Tips for Smarter Material Choices

- Chemical Resistance Needs: Think environments with acids or harsh solvents. PVC and polypropylene excel here.

- Temperature Considerations: For heat-facing components, PEEK or PTFE plastics may outperform others.

- Strength Under Load: Materials like acetal or nylon deliver top-tier mechanical durability.

Material Adaptability Across Applications

Projects differ, but adaptability separates a successful material pick from a problematic one. Industries like medical manufacturing prefer plastics resistant to wear and chemicals, while creative engineers might value flexibility over stiffness.

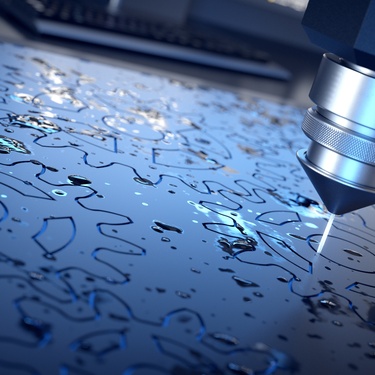

Designers working with CNC machines know that choosing the wrong plastic can cause significant delays, increase costs, and result in poor-quality parts. Choosing the right material can make or break projects, as selecting a misfit material risks mechanical failures or environmental incompatibility. Be clear about the balance of rigidity, flexibility, and resilience your project demands for smooth execution.

A Better Foundation for Long-Term Success

Your choices today impact more than just the immediate project; they build a legacy for future results. Material selection goes beyond fulfilling immediate needs; it is about long-term reliability, sustainable design, and project integrity. With clear priorities, technical data, and proactive decision-making, you address immediate tasks while ensuring your projects stand the test of time.

Bio: Casey is a passionate copyeditor highly motivated to provide compelling SEO content in the digital marketing space. Her expertise includes a vast range of industries from highly technical, consumer, and lifestyle-based, with an emphasis on attention to detail and readability.